Circular Comb

Key words:

card cloth

Classification:

Circular Comb

Product Details

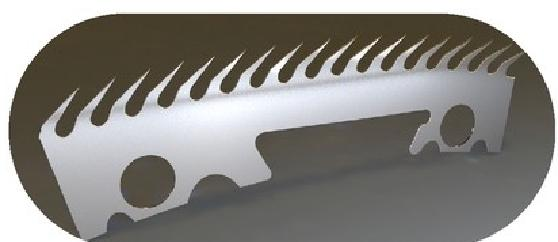

Features of Tooth Plate Circular Comb

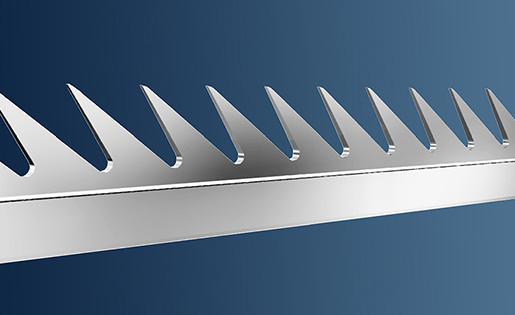

✥Digital modeled gear structure design, high-quality imported materials, exquisite manufacturing technology

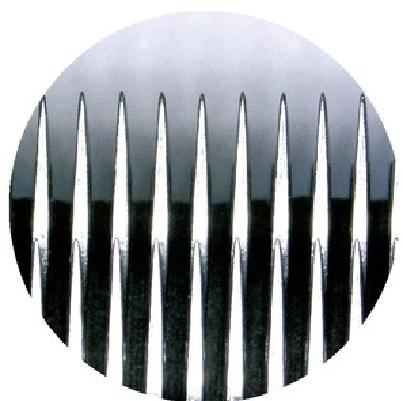

Patented conical tooth technology

The tooth tips are strong, wear-resistant, sharp and smooth

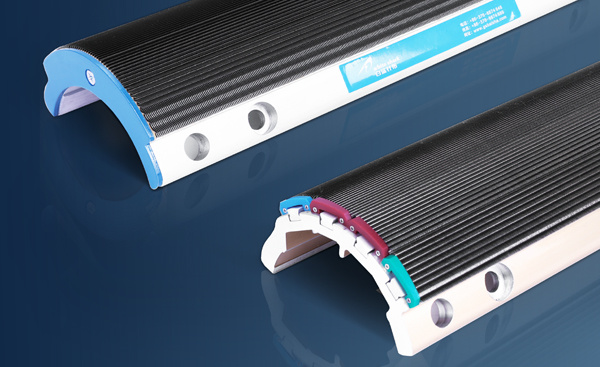

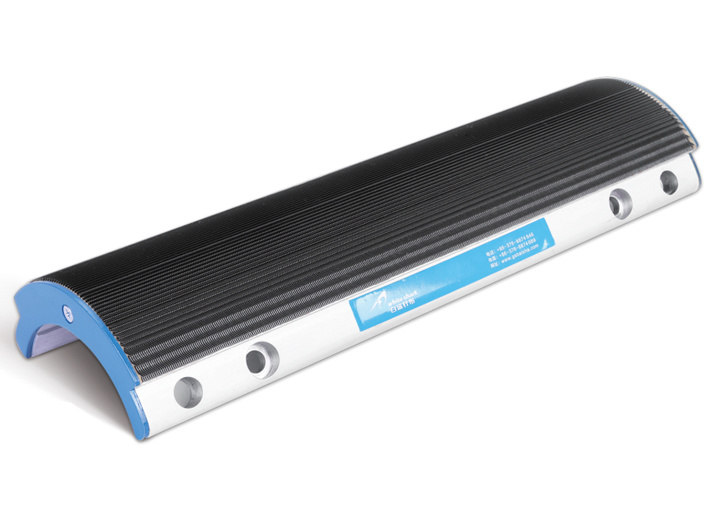

Tooth Plate Circular Comb

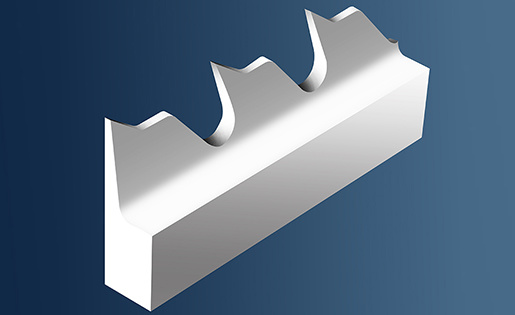

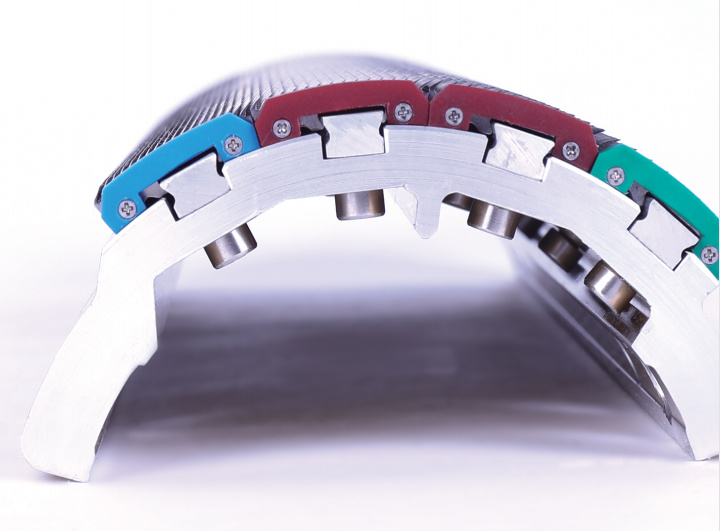

✥ Combined assembly, 90°/110° two carding surfaces, different density needle bar combinations, wide configuration range, adaptable to various combing equipment

✥ Stable combing effect, no inlay between teeth, adaptable to high clamping times and heavy weight

✥ Flexible carding to protect fibers and save cotton

✥ Easy to disassemble and replace, cost-effective, and compatible with international products

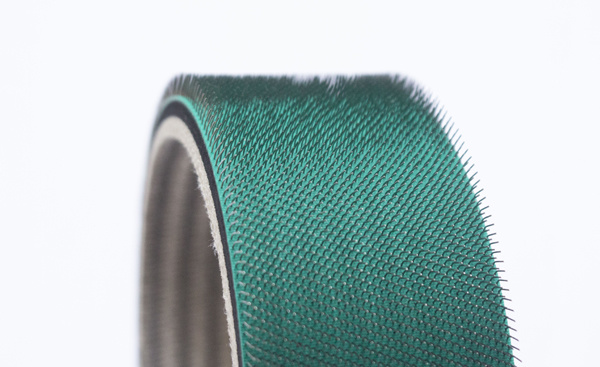

Circular Comb For Cotton Combing Machine

White Shark bonded cotton combed solid cylinder is derived from White Shark metal card clothing created by precision technology and patented process, and is manufactured through exquisite bending and bonding technology.

✥ High-quality high-carbon low-alloy steel wire, optimal needle tooth geometric structure design, leading manufacturing precision, tapered tooth technology and surface strengthening treatment create sharp, smooth, strong and wear-resistant metal needle teeth.

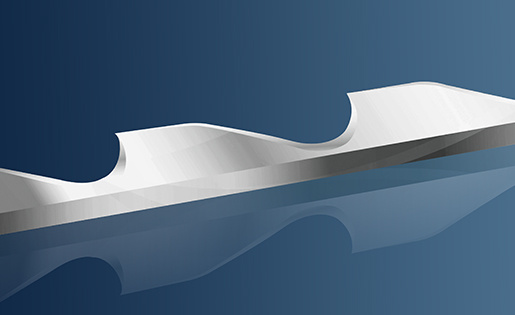

✥ Exquisite card clothing bending, needle density arrangement, tilt angle and needle tooth combing point control, strong bonding technology, hollow lightweight base, the product runs smoothly on the machine, and is suitable for high clamp weights.

✥ The bevel needle tip has smooth teeth, smooth puncture, and flexible combing to protect fibers.

✥ While removing lint, impurities, neps and cotton seeds, the fibers are arranged in parallel to soften waste and save raw cotton.

✥ The digitally modeled design of the total number of teeth of the combing cylinder and the spinning performance of the needle tooth needle type and the customer's carding requirements provide a full range of high-performance bonded combing cylinders.

Product inquiry